By definition, Temperature is a physical property of a material that manifests the thermal energy content of that material. Temperature expresses the relative measures of how hot or cold an object is with respect to another object.

- The hotness or coldness of a piece of plastic, wood, metal, or other material depends upon the molecular activity of the material.

- Kinetic energy is a measure of the activity of the atoms that make up the molecules of any material. Therefore, the temperature is a measure of the kinetic energy of the material under measurement.

Units of Temperature: Temperature Scales: Temperature Measurement Units

Temperature measurement units are the units used to express temperature in various systems of measurement. There are several temperature measurement units in use around the world, but the most commonly used units are the Celsius (°C) and Fahrenheit (°F) scales.

To standardize the temperature of objects under varying conditions, several temperature scales have been devised.

- Degree Celsius/ Centigrade Scale (C): A temperature scale defined by 0 Deg C at the ice point and 100 degrees C at the boiling point of water at sea level. This scale is commonly used in scientific and industrial applications.

- Fahrenheit Scale (F): A temperature scale defined by 32 Deg F at the ice point and 212 Deg F at the boiling point of water at sea level. This scale is commonly used in the United States and other countries that still rely on the Imperial system of measurement.

- Kelvin Scale (K): The unit of absolute or thermodynamic temperature scale based upon the Celsius with 100 units between the ice point and boiling point of water. 0 Deg C=273.15 K. This is used in scientific and engineering applications and is based on the absolute zero point.

- Rankine Scale (R): An absolute temperature scale based upon the Fahrenheit scale with 180 Deg between the ice point and boiling point of water. 0 Deg F=459.67 Deg R.

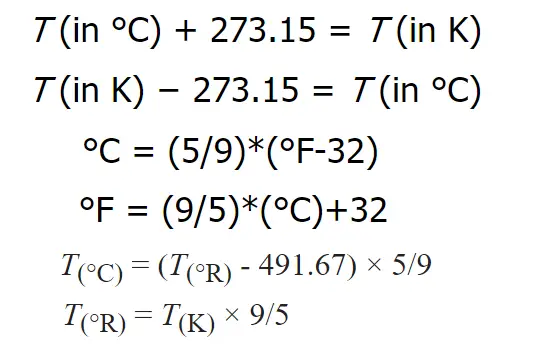

Conversion between Temperature Scales

The following image provides the formulas/equations for conversion from one temperature scale to the other.

Temperature Measurement Formulas

The formula for converting temperature between different units depends on the temperature scale being used. Here are some common formulas:

- Celsius to Fahrenheit: Fahrenheit temperature (°F) = (Celsius temperature x 1.8) + 32

- Fahrenheit to Celsius: Celsius temperature (°C) = (Fahrenheit temperature – 32) ÷ 1.8

- Celsius to Kelvin: Kelvin temperature (K) = Celsius temperature + 273.15

- Kelvin to Celsius: Celsius temperature (°C) = Kelvin temperature – 273.15

- Fahrenheit to Rankine: Rankine temperature (°R) = Fahrenheit temperature + 459.67

- Rankine to Fahrenheit: Fahrenheit temperature (°F) = Rankine temperature – 459.67

Temperature Measurement Instrumentation

In the dynamic and challenging landscape of the oil and gas industry, temperature measurement instrumentation plays a crucial role in ensuring operational efficiency, reliability, and safety. From upstream exploration and production to downstream refining and distribution, precise temperature monitoring is essential for optimizing processes, protecting assets, and mitigating risks.

Temperature measurement refers to the process of determining the degree of hotness or coldness of an object or environment, usually expressed in units such as Celsius (°C) or Fahrenheit (°F). Temperature is a physical quantity that indicates the amount of thermal energy present in an object, and it can be measured using a variety of instruments, such as thermometers, thermocouples, resistance temperature detectors (RTDs), and infrared sensors. Temperature measurement is important in many fields, including physics, chemistry, engineering, medicine, and meteorology, as it provides crucial information about the thermal properties of materials and their behavior under different conditions.

Temperature measurement instrumentation encompasses a broad array of devices and sensors designed to quantify thermal energy within various components and processes of the oil and gas industry. These instruments serve as essential tools for monitoring temperature fluctuations, identifying anomalies, and maintaining optimal operating conditions. From traditional mechanical instruments to advanced electronic sensors, temperature measurement instrumentation continues to evolve, driven by technological advancements and industry demands for greater accuracy, reliability, and efficiency.

Temperature Measurement Devices

A temperature measurement device is an instrument used to measure the temperature of an object or environment. There are various temperature measurement devices available, including:

- Thermometers: A thermometer is a device used to measure temperature, usually in degrees Celsius or Fahrenheit. It can be either a glass or digital thermometer, and it works by measuring the expansion or contraction of a liquid, such as mercury or alcohol, due to temperature changes.

- Thermocouples: A thermocouple is a temperature-measuring device that consists of two wires made of different metals that are joined together at one end. When the temperature changes, a voltage is generated, which can be measured to determine the temperature. More details about thermocouples can be found here

- Resistance Temperature Detectors (RTDs): RTDs are sensors that measure temperature by detecting changes in electrical resistance. They are made of a metal such as platinum or nickel and have a known resistance at a specific temperature.

- Infrared (IR) Sensors: IR sensors measure temperature without contacting the object being measured. They work by detecting the infrared radiation emitted by an object and converting it into a temperature reading.

- Bimetallic Strip Thermometers: A bimetallic strip thermometer uses two metals with different coefficients of thermal expansion to create a bend when heated, which can be measured to determine the temperature.

- Thermal Imaging Cameras: Thermal imaging cameras use infrared technology to detect and measure temperature differences across a surface, producing an image that shows the temperature distribution.

- Liquid Crystal Temperature Indicators: Liquid crystal temperature indicators use heat-sensitive liquid crystals that change color as the temperature changes, providing a visual indication of temperature.

- Non-Contact Pyrometers

- Intelligent Temperature Transmitters

These are just a few examples of the many temperature measurement devices available. The choice of device depends on factors such as accuracy, range, speed, and cost, as well as the application and environment in which it will be used.

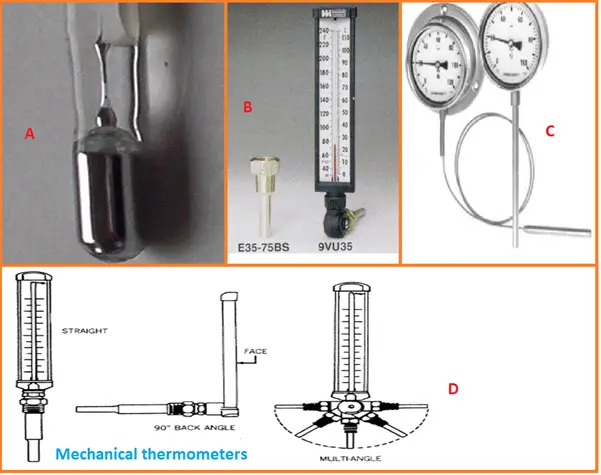

Temperature Measurement by Mechanical Thermometers

Liquid Filled Thermometers:

Calibrated marks on the tube allow the temperature to be read by the length of the mercury within the tube, which varies according to the temperature. To increase the sensitivity, there is usually a bulb of mercury at the end of the thermometer which contains most of the mercury; expansion and contraction of this volume of mercury are then amplified in the much narrower bore of the tube.

The space above the mercury may be filled with nitrogen or it may be a vacuum to increase the temperature range.

Industrial Mercury Thermometer:

Some manufacturers use a liquid alloy of gallium, indium, and tin, Galinstan, as mercury replacement. The industrial thermometer is used for a range of 0-538 degrees C

At this upper limit, the space above the mercury column must be under great pressure with an inert gas to prevent the evaporation of mercury from the top of the column.

Filled-type thermometers (Fig. 2, C) with thermo-well are used as a locally mounted temperature indicator, with extended capillary where necessary.

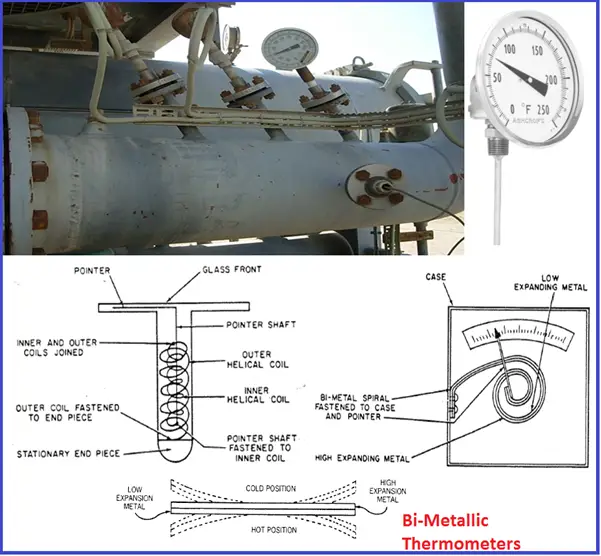

Bimetallic Thermometer:

Fundamental Principle:

- Metals change the volume with Temperature

- This coefficient of change is not the same for all metals.

Most industrial bimetal thermometers use a helical coil that can be designed to fit into a stem more easily. The element is surrounded by a protective wall.

Bimetal-type or filled-type dial thermometers with thermo-well is used for local temperature indication.

Temperature Measurement by Non-Contact Pyrometers

IR Pyrometers:

- Fundamental Principle: Radiation emitted by a Hot Body

- IR Pyrometers detect the dominant wavelength of the radiation received from a hot body.

- As temperature increases, the dominant wavelength of hot body radiation gets shorter.

- Range : 0-3890 DegC

- The IR Pyrometer must be carefully aimed to avoid focusing on reflected solar radiations

- When the temperature of a hard-to-reach area is required (Temperature of turbine blades inside Turbine Engines), IR Pyrometers are used.

Limitation: Changes in emissivity of the surface and by contamination and dirt buildup.

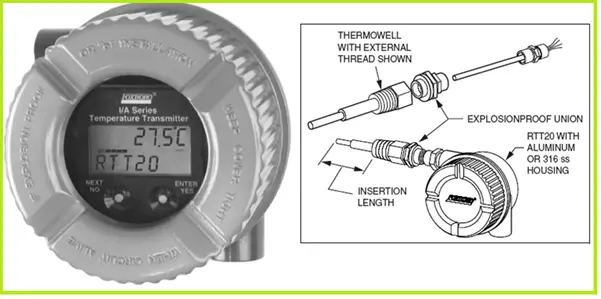

Temperature Measurement by Intelligent Temperature Transmitters (ITT)

- The incorporation of a microprocessor has improved the performance of Temperature Transmitters. These improvements include the near elimination of errors due to ambient temperature variations.

- An ITT usually provides a linear output with all its sensing elements and can also be reconfigured to accept any thermocouple, RTD, or millivolt sensors.

- The ITT automatically selects the right cold junction compensation to match the selected thermocouple.

- ITT is capable of handling dual RTD elements, allowing for temperature averaging, difference measurement, or automatic RTD sensor switchover if the primary sensor fails in a redundant installation.

Temperature Measurement Standards

Temperature measurement standards are guidelines, procedures, and protocols used to ensure accurate and consistent temperature measurements across different instruments, systems, and applications. These standards are developed and maintained by national and international organizations, such as the International Organization for Standardization (ISO), the National Institute of Standards and Technology (NIST), and the International Electrotechnical Commission (IEC).

Some of the commonly used temperature measurement standards include:

- International Temperature Scale (ITS): The ITS is a standardized temperature scale that defines the relationship between temperature and certain physical properties, such as the thermal expansion of certain materials. It provides a common reference point for calibrating temperature measurement devices and is used to establish traceability to national and international standards.

- Calibration standards: Calibration standards are reference materials and instruments used to calibrate temperature measurement devices. These standards provide a known, stable temperature, and are used to verify the accuracy and reliability of thermometers, thermocouples, RTDs, and other temperature measurement devices.

- Standard Operating Procedures (SOPs): SOPs are documents that describe the steps and procedures for conducting temperature measurements. They ensure consistency and repeatability across different measurement procedures and provide guidance for users to perform temperature measurements correctly and accurately.

- Traceability: Traceability is the ability to trace the measurement results back to the original reference standard or calibration source. Traceability provides a documented chain of measurement and calibration that ensures the accuracy and reliability of temperature measurements.