The two most important terms used in the Pump Industry are Net Positive Suction Head (NPSH) Available & Net Positive Suction Head Required. These terms have an impact on the pump’s efficiency, life, power consumption, and overall OPEX cost. So, in Today’s article, we will discuss the fundamentals of Net Positive Suction Head (NPSH).

What is NPSH?

In general terms, the net positive suction head is the pressure required at the pump inlet to avoid Cavitation. Since NPSH is expressed in terms of absolute fluid column height in meter head or feet head it is always positive. This pressure should be greater than the vapor pressure of the fluid so that the problem of cavitation can be avoided in the pump.

What is Cavitation?

Cavitation occurs in a fluid flow system where the pressure of liquid starts falling below its vapor pressure. Due to this, the liquid starts boiling and bubbles are formed. When these bubbles explode, they erode the surface of the system. This phenomenon is known as cavitation.

If cavitation of the pump is not stopped at an early stage it may lead to abnormal vibrations in the pump body, damage to pump bearings, churning sound, the impeller surface may get eroded and finally, the impeller also gets damaged.

What Is NPSHA?

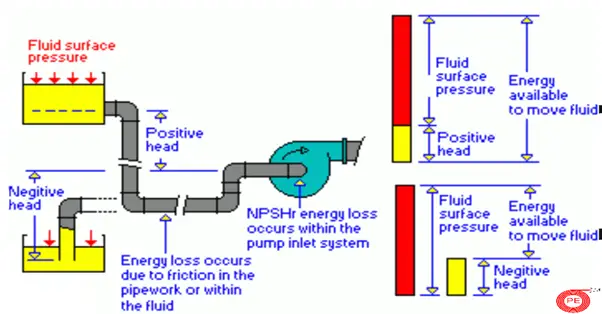

NPSHA or Net Positive Suction Head Available is generally provided by the system designer or process engineer of the particular system. The value of NPSHA varies from system to system. It is dependent on the fluid temperature, the pressure exerted by the atmosphere on the fluid, losses in the pump suction side, pump static lift, or static height of fluid (generally taken from Low Water level to the top surface of fluid).

What is NPSHR?

NPSHR or Net Positive Suction Head Required is the minimum suction head required at the pump suction flange. It is provided by a pump supplier or pump manufacturer. The value of NPSHR is calculated by pump suppliers by testing the pump in their workshops. The value of NPSHR varies from pump supplier to supplier. This value also varies from the pump model to the model.

Relation Between NPSHA & NPSHR

As already mentioned, the NPSH(R) is the minimum required head at the pump suction flange to avoid cavitation of the pump. So, in order to avoid cavitation NPSH(A) should always be greater than NPSH(R).

If the value of NPSHA falls below the value of NPSHR a low vapor pressure will be formed at the pump suction. Due to low vapor pressure, the water will start boiling even without attaining the boiling point. Because of these, bubbles of water will start forming, these bubbles will reach the pump impeller eye and due to low pressure at the pump impeller eye, they will explode there. This explosion of bubbles will lead to the deterioration of the pump impeller with many more problems.

For a more detailed explanation regarding NPSHA & NPSHR watch the video attached below

Calculation of NPSHA

As mentioned above NPSHA is calculated by the process designer for a particular system. The formulae to calculate NPSHA are given below:

NPSHA = HA ± HZ – HF + HV – HVP

| Term | Detail of Term | Considerations |

| HA (mWc) | The absolute pressure on the surface of the liquid in the supply tank | Typically, atmospheric pressure (vented supply tank), but can be different for closed tanks. |

| HZ (mWc) | The vertical distance between the surface of the liquid in the supply tank and the centreline of the pump | Can be positive when the liquid level is above the centreline of the pump (called the static head) Can be negative when the liquid level is below the centreline of the pump (called suction lift) Always be sure to use the lowest liquid level allowed in the tank. |

| HF (mWc) | Friction losses in the suction piping. | Piping and fittings act as an obstruction (restriction), working against liquid as it flows towards the pump inlet. |

| HV (mWc) | Velocity head at the pump suction port | Often not included as it’s normally quite small. |

| HVP (mWc) | Absolute vapor pressure of the liquid at the pumping temperature | Must be subtracted in the end to make sure that the inlet pressure stays above the vapor pressure. Remember, with an increase in temperature, vapor pressure also goes up. |

The formulae mentioned above can be further simplified to the below-mentioned formulae. This formula is used by process engineers to calculate NPSHA for the pumping system.

NPSH(A)= P(atm) + Static head – frictional head loss in the suction side – Vapour Pressure of Water

Negative Impacts of NPSH on Pumping System

- Impeller Erosion

- Pump Vibration

- Sound

- Bearing Damage

- High Power Consumption

- Low Pump Efficiency

Hence, the available NPSH is very important while designing and selecting a pump for a process.

For a more detailed explanation of the Calculation of NPSH(A) please watch the following video. For more updates on similar video articles please like the Channel: Piping Engineers