In the world of fluid transfer and pumping technology, one remarkable innovation stands out for its simplicity, versatility, and precision – the peristaltic pump. Developed more than a century ago, peristaltic pumps have evolved into a critical tool across various industries, offering a unique pumping mechanism that finds applications in medicine, laboratory research, food and beverage, water treatment, and beyond. In this blog, we’ll delve into the fascinating world of peristaltic pumps, exploring how they work, their advantages, and their diverse range of applications.

What is a Peristaltic Pump?

A peristaltic pump is a type of positive displacement pump that uses a unique mechanism to transfer fluids. It operates by using a flexible tube or hose that is squeezed and released by a series of rollers or shoes, creating a “milking” or peristaltic action. This action propels the fluid through the tube in a controlled manner. Peristaltic pumps are also known as roller pumps, tube pumps, or hose pumps.

Components of a Peristaltic Pump

The primary components of a peristaltic pump include:

- Flexible Tubing: The heart of a peristaltic pump is the flexible tubing or hose through which the fluid flows. This tubing is typically made from materials that are compatible with the fluid being pumped, such as various types of elastomers, silicones, or other specialized materials.

- Rollers or Shoes: These are mechanical components that move along the length of the tubing. The rollers or shoes compress the tubing against a fixed surface, creating a temporary seal and pushing the fluid forward. As the rollers move, they release the pressure on the tubing, allowing it to rebound and draw more fluid into the pump.

- Pump Housing: The tubing is usually positioned within a circular pump housing that guides the movement of the rollers or shoes. The housing ensures that the peristaltic action is smooth and controlled.

Tubing for Peristaltic Pumps

The choice of tubing for peristaltic pumps is a crucial factor that directly impacts the performance, efficiency, and longevity of the pump. Different tubing materials are suitable for various fluids, applications, and environmental conditions. Here are some commonly used tubing materials for peristaltic pumps:

- Silicone: Silicone tubing is a versatile option with good flexibility and a wide temperature range. It is compatible with many fluids, including pharmaceuticals, food and beverage products, and some chemicals. However, it may not be suitable for aggressive chemicals or solvents.

- Santoprene: Santoprene is a thermoplastic elastomer that offers excellent chemical resistance, making it suitable for pumping a variety of fluids, including some corrosive and abrasive substances. It is commonly used in industrial and chemical applications.

- Tygon: Tygon tubing is known for its flexibility and clarity, allowing visual monitoring of fluid flow. It comes in various formulations, each designed for specific applications, such as laboratory, pharmaceutical, or food processing.

- Pharmed: Pharmed tubing is a type of thermoplastic elastomer tubing that is highly biocompatible and resistant to a wide range of chemicals. It is often used in medical and pharmaceutical applications, as well as laboratory settings.

- Viton: Viton tubing is highly resistant to aggressive chemicals, high temperatures, and UV radiation. It is suitable for pumping corrosive and abrasive fluids, but it may have a limited temperature range compared to other materials.

- Norprene: Norprene tubing is a thermoplastic elastomer known for its chemical resistance and long service life. It is often used in industrial and laboratory applications.

- PEEK: Polyetheretherketone (PEEK) tubing offers excellent chemical resistance and can handle high temperatures. It is commonly used in analytical and research applications.

- Teflon (PTFE): Teflon tubing is known for its exceptional chemical resistance, making it suitable for aggressive and corrosive fluids. It is often used in industrial and chemical applications.

- Natural Rubber: Natural rubber tubing is suitable for some general-purpose applications and can handle certain fluids. However, it may not be as chemically resistant as other materials.

When selecting tubing for your peristaltic pump, consider the following factors:

- Fluid Compatibility: Choose a tubing material that is compatible with the specific fluid you are pumping. Consider the chemical composition, temperature, and any potential interactions.

- Application Requirements: Evaluate the temperature range, pressure, and flow rate requirements of your application.

- Abrasion and Wear: If pumping abrasive or viscous fluids, consider tubing materials with good wear resistance.

- Flexibility: The tubing should be flexible enough to allow the peristaltic action to work effectively.

- Sterilization and Cleanability: In applications requiring sterility or frequent cleaning, choose a tubing material that can be easily sterilized or cleaned.

- Longevity: Some tubing materials have longer service lives than others. Consider how often tubing replacement will be needed.

- Regulatory Compliance: In industries like pharmaceuticals or food processing, ensure that the tubing material complies with relevant regulatory standards.

Consult with the pump manufacturer or a tubing supplier to determine the best tubing material for your specific peristaltic pump application.

Working Principle of Peristaltic Pumps

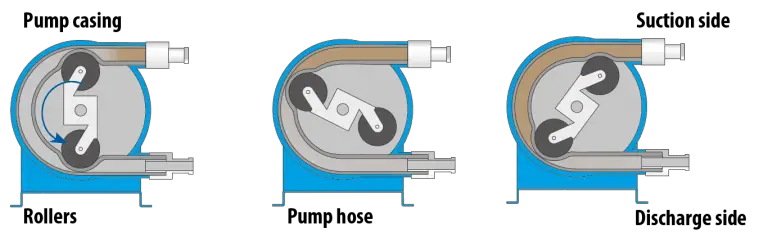

The peristaltic pump works on the principle of peristalsis, which is the natural rhythmic, wave-like contraction and relaxation of muscles seen in biological systems, such as the human digestive system. The pump consists of a flexible tube or hose placed within a circular pump housing. The tube is compressed by a series of rollers or shoes that move along the tubing, creating a “milking” action that propels fluids through the tube in a controlled manner. As the rollers advance, they squeeze the tube shut, forcing the fluid within to move forward. Once the rollers move past, the tube rebounds to its original shape, creating a vacuum effect that draws more fluid into the tube. This unique mechanism offers a number of advantages that set peristaltic pumps apart from traditional pump designs.

The working of a peristaltic pump consists of two phases

- Squeezing Phase: As a roller or shoe moves along the tubing, it squeezes the flexible tube against a solid surface, effectively closing off the tube at that point. This squeezing action creates a positive displacement, pushing the fluid in the tubing in the direction of the pump outlet.

- Recovery Phase: Once the roller or shoe moves past, the tubing rebounds to its original shape due to its elasticity. This rebound creates a vacuum effect, which draws more fluid from the inlet into the tubing, ready for the next squeezing phase.

The following figure clearly explains the working of a peristaltic pump.

Types of Peristalic Pumps

Peristaltic pumps are commonly categorized based on their pressure-handling capabilities into two groups; low-pressure peristaltic pumps and high-pressure peristaltic pumps.

Low-pressure peristaltic pumps belong to the laboratory-grade category and are specifically engineered for applications involving low-pressure fluid transfer. Examples include their use in intravenous (IV) systems for medical fluid administration and for precise chemical metering. These pumps typically feature casings without moisture and reinforcement and employ rollers to exert the required compressive force.

On the other hand, high-pressure peristaltic pumps fall under the industrial-grade classification and are designed to handle demanding tasks such as pumping aggressive sewage and thick slurries under high-pressure conditions. These pumps are equipped with casings that are coated with lubricants to prevent damage caused by friction and abrasion while also aiding in heat dissipation. Additionally, these pumps utilize robust, reinforced tubes engineered to withstand the intense pressures involved in their applications.

Again depending on the size of the peristaltic pumps they are classified as mini peristaltic pumps, micro peristaltic pumps, small peristaltic pumps, and large peristaltic pumps.

- Mini Peristaltic Pumps: Mini peristaltic pumps are compact and designed for applications that require relatively low flow rates. They are often used in situations where space is limited or where precision dosing is essential. Mini pumps are suitable for laboratory use, small-scale experiments, and applications where a small amount of fluid transfer is needed.

- Micro Peristaltic Pumps: Micro peristaltic pumps are even smaller than mini pumps and are designed for very low flow rates, often in the microliter range. They are used in applications requiring extremely precise fluid handling, such as microfluidics, microreactors, and certain medical or analytical procedures.

- Small Peristaltic Pumps: Small peristaltic pumps typically offer moderate flow rates and are suitable for a wide range of applications. They may be used in laboratories, research settings, and various industries for tasks such as dosing, sampling, and liquid transfer.

- Large Peristaltic Pumps: Large peristaltic pumps are designed to handle high flow rates and are used in applications where bulk fluid transfer is required. These pumps are commonly employed in industrial processes, wastewater treatment, and other scenarios involving the transfer of substantial volumes of fluids.

Advantages of Peristaltic Pumps

- Gentle Fluid Handling: Peristaltic pumps are known for their gentle handling of delicate or shear-sensitive fluids. Since the fluid only comes into contact with the tubing, there is minimal risk of contamination or degradation.

- Precise Flow Control: The rhythmic compression of the tubing allows for precise control over flow rates. This accuracy is particularly valuable in applications that require consistent dosing or mixing of fluids.

- Self-Priming: Peristaltic pumps are self-priming, meaning they can start pumping without the need for manual priming or complex setup procedures. This is especially useful in situations where maintaining fluid integrity is crucial.

- Minimal Maintenance: With few moving parts and a simple design, peristaltic pumps require minimal maintenance. Tube replacement is the primary maintenance task, and it can often be done quickly and easily.

- Versatile Tubing Options: Peristaltic pumps can accommodate a wide range of tubing materials, allowing them to handle various fluids, from aggressive chemicals to viscous substances.

Applications Across Industries

Industrial peristaltic pumps find application in the following industries.

- Medical and Pharmaceutical: Peristaltic pumps are widely used in medical applications such as drug delivery, dialysis, Medical infusion pumps, Open-heart bypass pump machines, and patient monitoring. Their ability to provide accurate dosing and minimize contamination makes them invaluable tools in healthcare.

- chemical dosing

- liquid protein

- vaccines

- serum, plasma

- syrups

- shampoos, etc

- Laboratory Research: Peristaltic pumps are a staple in laboratories for tasks like liquid chromatography, carbon monoxide monitors, media dispensers, sample preparation, autoanalyzer, and cell culturing. Their precision and gentle fluid handling are vital for maintaining accurate experimental conditions.

- Food and Beverage: In the food and beverage industry, peristaltic pumps are employed for transferring sensitive ingredients, such as flavorings, colorants, and additives. Their sanitary design and ease of cleaning ensure product quality and safety. Other uses of peristaltic pumps in food and beverage industries are:

- Liquid food fountains

- Food-service Washing Machine fluid pump

- Beverage dispensing

- Environmental and Water Treatment: Peristaltic pumps play a role in water treatment processes, dosing chemicals and additives into the water stream for purification and disinfection.

- Sewage sludge

- Chemical treatment in water purification plant

- Automatic wastewater sampling for wastewater quality indicators

- Aquariums, particularly calcium reactors

- Engineering and manufacturing:

- Pulp and paper plants

- Concrete pump

- Inkjet printers

- Minimum quantity lubrication

- Chemical handling:

- Pharmaceutical production

- Printing, paint, and pigments

- Dosing systems for dishwasher and laundry chemicals

- Surface Treatment:

- Abrasive waste fluids, acids, alkalis, paints

- Electrolytic zinc plating

- Copper, Nickel, Tin, Silver, and Gold plating,

- Alcalic zinc, Zinc-iron, Zinc-nickel, Hexavalent Chromium-free plating

- Chromates / Passivation

- Acid zinc

- Industrial Processes: From chemical processing to industrial wastewater treatment, peristaltic pumps offer a reliable solution for transferring fluids in harsh and corrosive environments.

How to Specify a Peristaltic Pump?

Specifying a peristaltic pump involves defining the pump’s key parameters and features to ensure it meets the specific requirements of your application. Here’s a step-by-step guide on how to specify a peristaltic pump:

- Identify Application Requirements: Begin by understanding the nature of your application and the fluids you’ll be pumping. Determine factors such as flow rate, pressure, fluid viscosity, temperature, and chemical compatibility. Also, consider any special requirements like sterile conditions or precise dosing.

- Flow Rate and Pressure: Calculate or estimate the required flow rate and pressure for your application. Different peristaltic pumps have varying maximum flow rates and pressure capabilities. Ensure the pump you choose can handle your desired parameters.

- Fluid Compatibility: Select tubing materials that are compatible with the fluid you’re pumping. Different tubing materials are suitable for different types of fluids, including aggressive chemicals, viscous substances, or sensitive biological materials.

- Tubing Size and Configuration: Determine the tubing size and configuration that best suits your application. Tubing size affects flow rate, and different configurations (single, double, or continuous loop) have their own advantages based on flow consistency and ease of maintenance.

- Precision and Accuracy: If your application requires precise dosing or accurate fluid delivery, consider pumps with features like variable speed control or stepper motor-driven mechanisms. These can provide the level of precision you need.

- Maintenance and Tubing Replacement: Evaluate how frequently you’ll need to replace the tubing and how easy it is to perform this task. Quick and hassle-free tubing replacement can save time and maintenance costs.

- Environmental Considerations: Consider the operating environment of the pump. If it will be exposed to harsh chemicals, extreme temperatures, or other challenging conditions, choose a pump that can withstand them.

- Pump Head Material and Design: The pump head (where the tubing is compressed) should be made of durable and chemically resistant materials, especially if the pumped fluid is aggressive or abrasive.

- User Interface and Controls: Determine if you need specific control options, such as analog or digital control, remote control capability, or integration with other equipment.

What are High Flow Peristaltic Pumps?

High-flow peristaltic pumps are a type of peristaltic pump designed to handle larger volumes of fluid at higher flow rates. These pumps are specifically engineered to cater to applications that require rapid fluid transfer while maintaining the advantages of peristaltic pumping, such as gentle handling of the fluid and precise control. High-flow peristaltic pumps are commonly used in various industries where efficient and controlled fluid transfer is essential.

Key Features of High-Flow Peristaltic Pumps:

- Enhanced Flow Rates: High-flow peristaltic pumps are designed to accommodate significantly higher flow rates compared to standard peristaltic pumps. They are capable of transferring larger volumes of fluid within a shorter period.

- Robust Construction: These pumps are often built with durable materials and reinforced components to withstand the mechanical stress associated with higher flow rates.

- Variable Speed Control: Many high-flow peristaltic pumps offer variable speed control, allowing operators to adjust the flow rate according to the specific requirements of the application.

- Precision and Accuracy: Despite their higher flow rates, these pumps maintain the peristaltic pumping mechanism’s inherent precision and accuracy, making them suitable for applications that demand controlled dosing and accurate fluid transfer.

What are Multichannel Peristaltic Pumps?

Multichannel peristaltic pumps are specialized variations of peristaltic pumps that feature multiple independent channels or tubing paths within a single pump head. These pumps are designed to simultaneously transfer multiple fluids or samples, each through its own separate tubing pathway. Multichannel peristaltic pumps offer several advantages in applications where precise and simultaneous fluid handling is required.

Features of Multichannel Peristaltic Pumps:

- Multiple Channels: The defining feature of multichannel peristaltic pumps is the presence of two or more separate tubing paths within a single pump head. Each channel operates independently, allowing for the simultaneous transfer of different fluids or samples.

- Individual Control: Multichannel pumps offer the capability to control each channel independently. This allows for precise control over flow rates, dosing, and timing for each fluid being pumped.

- Precision and Accuracy: These pumps maintain the inherent precision and accuracy of peristaltic pumping for each individual channel, ensuring reliable and consistent fluid transfer.

- Reduced Contamination Risk: Because each channel is isolated, the risk of cross-contamination between different fluids or samples is minimized, making multichannel peristaltic pumps suitable for applications where maintaining sample purity is critical.

- Space Efficiency: Multichannel pumps provide the advantage of handling multiple fluids within a single pump unit, saving space and reducing the need for multiple individual pumps.

What are OEM Peristaltic Pumps?

OEM (Original Equipment Manufacturer) peristaltic pumps are specialized pumps designed for integration into original equipment or systems developed by other manufacturers. These pumps are often customized or tailored to meet the specific requirements and specifications of the OEM customer. In other words, OEM peristaltic pumps are pumps that are manufactured by one company but then used as a component or subsystem in the products of another company.

Key features and characteristics of OEM peristaltic pumps include:

- Modularity: OEM peristaltic pumps are designed to be modular, allowing them to be easily integrated into existing equipment or systems. This modularity facilitates seamless integration and minimizes the need for extensive modifications.

- Customization: OEM peristaltic pumps can be customized to fit the unique needs of the OEM customer. This customization may involve adjusting flow rates, pressure capabilities, tubing materials, dimensions, and other specifications to match the requirements of the larger system.

- Compact Design: These pumps are often designed to be compact and space-efficient, making them suitable for integration into various types of equipment without adding excessive bulk.

- Reliability: OEM peristaltic pumps are engineered to deliver consistent and reliable fluid transfer, ensuring that the larger system performs as intended.

- Ease of Integration: OEM peristaltic pumps come with features that facilitate easy integration, such as standardized interfaces, mounting options, and electrical connections.

- Long-Term Partnerships: Manufacturers of OEM peristaltic pumps often establish long-term partnerships with OEM customers to provide ongoing support, technical assistance, and customized solutions.

Peristaltic Pumps Manufacturers

There are several manufacturers that produce peristaltic pumps, offering a range of models and configurations to meet various industrial, medical, laboratory, and research needs. Here are some well-known peristaltic pump manufacturers:

- Watson-Marlow: A leading manufacturer of peristaltic pumps, Watson-Marlow offers a wide range of pumps suitable for various industries, including pharmaceuticals, biotechnology, food and beverage, and more.

- Cole-Parmer: Cole-Parmer produces a diverse selection of peristaltic pumps for laboratory, industrial, and OEM applications. They offer pumps with different flow rates and capabilities to suit different needs.

- Masterflex: A brand under Cole-Parmer, Masterflex is known for its comprehensive line of peristaltic pumps and pump systems designed for accurate fluid handling in laboratory and industrial settings.

- Verderflex: Verderflex specializes in peristaltic pumps for challenging applications, including heavy-duty and abrasive fluids. Their pumps find applications in industries like mining, water treatment, and chemical processing.

- Ismatec: Ismatec, another brand under Cole-Parmer, is known for its precision peristaltic pumps and pump systems used in analytical and research applications.

- Alitea (A part of Thermo Fisher Scientific): Alitea offers peristaltic pumps designed for liquid handling and chromatography applications. They provide solutions for laboratories and research facilities.

- Flexicon (A part of Watson-Marlow): Flexicon specializes in aseptic peristaltic filling and capping systems for pharmaceutical and biotech industries.

- Gilson: Gilson offers a range of peristaltic pumps designed for liquid chromatography and other laboratory applications, providing accurate and reliable fluid delivery.

- Randolph Austin: This manufacturer produces industrial-grade peristaltic pumps for heavy-duty applications such as mining, construction, and wastewater treatment.

- KNF Neuberger: KNF offers peristaltic pumps for laboratory, industrial, and OEM applications, focusing on precise liquid transfer and dosing.

- Longerpump: Longerpump provides peristaltic pumps for medical, laboratory, and industrial use, with a focus on accurate fluid handling and reliable performance.

Disadvantages of Peristaltic Pumps

While peristaltic pumps offer numerous advantages, they also come with certain disadvantages that should be considered when choosing a pump for a specific application. Here are some of the disadvantages of peristaltic pumps:

- Limited Pressure and Flow Rates: Peristaltic pumps may have limitations in terms of maximum pressure and flow rates compared to some other types of pumps. High-pressure or high-flow applications may require larger or more powerful pumps.

- Pulsation: The peristaltic pumping action can result in pulsation in the fluid flow, which may not be suitable for applications that require a continuous and smooth flow, such as some analytical processes.

- Tube Wear and Replacement: The flexible tubing used in peristaltic pumps is a wear component and will eventually need to be replaced. Frequent tube replacement can lead to downtime and increased maintenance costs.

- Fluid Sensitivity: Some fluids, particularly those with high viscosity or containing particulate matter, can cause increased wear and abrasion on the tubing, leading to more frequent tube replacements and potential maintenance challenges.

- Limited Suction Lift: Peristaltic pumps may have limitations in their ability to lift fluids from deep or elevated sources due to their self-priming mechanism. This can be a limitation in certain applications.

- Complex Fluids: Handling complex fluids, such as those containing air bubbles or foam, can be challenging for peristaltic pumps. Air in the tubing can affect the pumping action and lead to inconsistent flow.

- Shear Sensitivity: While peristaltic pumps are generally gentle on fluids, some shear-sensitive materials may still experience slight shear forces during the pumping process, potentially affecting their properties.

- Limited Viscosity Range: Peristaltic pumps may struggle with very high-viscosity fluids, as the pumping action may require significant force to move thick fluids through the tubing.

- Size and Portability: In some cases, peristaltic pumps may be larger and less portable compared to certain other types of pumps, which can be a consideration in applications with limited space.

- Cost: Depending on the specific model and application, peristaltic pumps can be more expensive upfront than some other types of pumps.

- Complex Maintenance: While peristaltic pumps generally require minimal maintenance, replacing tubing and ensuring proper alignment of rollers or shoes can still require technical expertise.

Conclusion

Peristaltic pumps are a testament to the power of simple yet effective engineering. Their peristaltic action, precise flow control, and versatility have made them indispensable tools across a wide range of industries. As technology continues to evolve, peristaltic pump designs are likely to become even more sophisticated, enabling new applications and innovations that further enhance their impact. Whether in medical laboratories or industrial settings, peristaltic pumps are sure to remain a cornerstone of fluid transfer solutions for years to come.