Virtual Pipelines are an innovative solution for transporting natural gas. We all know that the traditional method of LNG or CNG is through conventional pipelines. However, generating the infrastructure for setting up pipelines is not only costly but also limited by geography. At the same time, The design and construction of such pipelines take years for successful pipeline commissioning. This is where the concept of virtual pipelines comes into play. The implementation of virtual pipelines will be able to meet the increasing demand for reliable energy sources. In this article, we will learn about the meaning, components, working, advantages, and examples of virtual pipelines in detail.

What is a Virtual Pipeline? Meaning of Virtual Pipelines

Virtual pipelines are an innovative and flexible method for natural gas transport from the production source to the end-user without using the traditional fixed pipelines. In this method, the natural gas is transported in its liquefied or compressed form. As the liquefaction reduces the volume, it takes much less space and can easily be transported using trucks, ships, trailers, and containers. The term “virtual” is provided as the transport does not involve the usual pipeline networks. The natural gas via virtual pipelines is transported in the form of LNG or CNG. As a result, they are known as LNG virtual pipelines or CNG virtual pipelines. In recent times, modularized mobile fuel transport through virtual pipelines has become much more popular.

Components of Virtual Pipelines

For efficient and economic transportation of natural gas, virtual pipelines comprised of several key components as mentioned below:

Transport Modes or Forms:

Virtual pipelines transport the natural gas in any one of the two forms:

Compressed Natural Gas (CNG): In this form, the natural gas is compressed and stored in specially designed high-pressure containers or tubes mounted on trailers for transportation.

Liquefied Natural Gas (LNG): In this mode, the natural gas is cooled to cryogenic temperatures (-162°C) and stored in insulated double-walled tanks before transportation.

Flexible Infrastructure:

Temporary on-site compression units known as mobile compression units and storage facilities are required for CNG virtual pipelines. Finally, the transportation of CNG and LNG in Virtual Pipelines is done using specialized vehicles. Each transport vehicle is equipped with safety features and controls to ensure the secure transport of the gas. Virtual pipelines can be quickly established and adapted to diverse geographical locations.

Modular Design:

Recent technological advancements helped the virtual pipeline components to become modular for scaling up or down to match the demand.

Working Principle of Virtual Pipelines

The process of virtual pipelines involves the following key steps:

Step 1: Gas Sourcing: Natural gas is typically sourced from conventional production facilities or unconventional sources like biogas, landfill gas, or stranded gas reserves.

Step 2: Compression or Liquefaction: Depending on the chosen transportation mode, natural gas is either compressed to high pressure (CNG) or liquefied at cryogenic temperatures (LNG).

Step 3: Temporary Storage: The compressed or liquefied natural gas is temporarily stored in containers or tanks at a central hub.

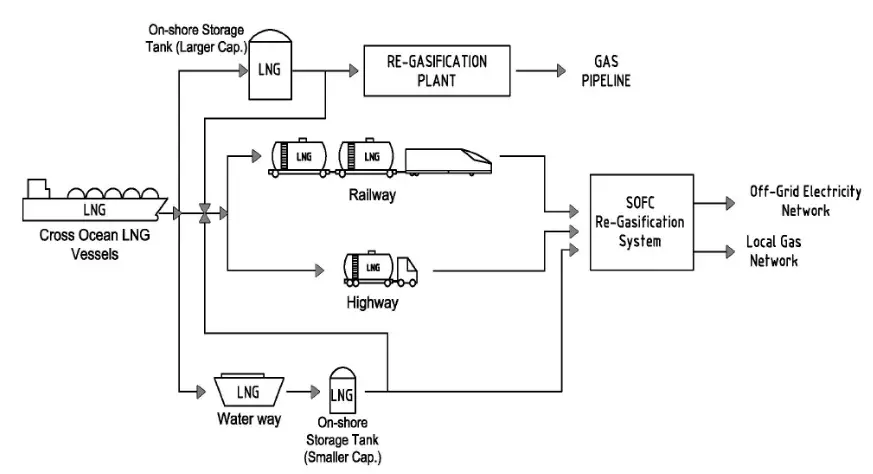

Step 4: Transportation: Natural gas is loaded onto specialized vehicles, such as CNG trailers, ISO containers, LNG ships, railways, or trucks. Refer to Fig. 1 (Image Credit: https://epcmholdings.com/virtual-pipelines/) which schematically explains a typical virtual pipeline working philosophy.

Step 5: Delivery: The gas is transported to its destination, which could be an industrial facility, power plant, or distribution network.

Step 6: Decompression or Regasification: At the destination, CNG is depressurized, or LNG is regasified, returning the gas to its gaseous state.

Step 7 (Final Step): Distribution: The natural gas is then distributed to end-users via pipelines or other appropriate means.

Advantages of Virtual Pipelines

The main advantages of virtual pipelines are:

- Virtual pipelines can easily serve remote areas where conventional pipeline construction is difficult.

- Transporting gases using LNG or CNG virtual pipelines mode is economical and quick.

- The use of virtual pipelines provides unmatched flexibility that conventional pipelines can not provide.

Advantages of Virtual Pipelines Over Conventional Pipelines

The virtual pipeline mode of transport and distribution systems allow suppliers to transport natural gas safely and economically to consumers without access to existing pipelines. The major advantages of virtual gas pipelines over conventional pipeline systems are.

- The requirement for consumers to link to the national gas grids is eliminated.

- Virtual pipelines ensure a dependable and uninterrupted provision of an environmentally friendly energy source

- It empowers consumers to cater to their individual requirements with adaptable supply options

- The option of virtual pipeline transport and distribution entails no upfront investment as consumers have the option to lease gas supply equipment

- It provides loading and unloading capabilities for direct connections at all stations

Future Prospects and Developments

The future of virtual pipelines holds several exciting possibilities and developments:

Technology Advancements: Continuous advancements in compression, liquefaction, and transportation technologies will improve the efficiency and safety of virtual pipelines.

Renewable and Sustainable Gases: Virtual pipelines may play a role in transporting renewable gases like biomethane and hydrogen, further contributing to decarbonization efforts.

Hybrid Energy Systems: Combining virtual pipelines with other energy solutions, such as renewable energy and energy storage, can create more resilient and sustainable energy ecosystems.

International Expansion: Virtual pipelines may facilitate the global trade of natural gas, allowing countries with abundant resources to export to those with growing demand.

Integration with Smart Grids: Integrating virtual pipelines into smart grid systems can enhance the overall efficiency and reliability of energy distribution.

Examples of Virtual Pipelines

Some of the real-world examples of virtual pipeline systems are given below:

1. Gas Innovations, a Texas-based company, operates a Virtual Pipeline system that supplies industrial gases, including natural gas, to customers across the United States. They utilize a fleet of specialized transport trailers to deliver CNG and LNG to customers, ensuring a reliable and cost-effective source of energy for various industrial applications.

2. Ferus Natural Gas Fuels, based in Canada, specializes in providing LNG solutions to the energy, mining, and transportation sectors. They operate Virtual Pipelines that transport LNG to remote mine sites, helping reduce emissions and energy costs for these operations.

3. VayuGrid, an Indian company, focuses on delivering natural gas to remote and off-grid areas in India. They use Virtual Pipelines to bring CNG to locations that were previously without access to clean energy sources, benefiting both residential and industrial users.