Developed by the American Petroleum Institute, API 617 is a standard that defines the minimum requirements and recommendations for axial compressors, single-shaft and integrally geared process centrifugal compressors, and expander-compressors used in the process, chemical, petrochemical, and gas industries. Let’s break it down:

- Axial Compressors: These compressors operate by drawing air or gas into the center of the compressor and then accelerating it in an axial direction. They are commonly used in applications like jet engines and industrial processes.

- Centrifugal Compressors: Also known as radial compressors, these oil-free dynamic air compressors convert introduced kinetic energy into increased potential energy. They find use in various industrial processes.

- Expander-Compressors: These machines serve a dual purpose—they can expand gases (such as in power generation) or compress gases (similar to centrifugal compressors).

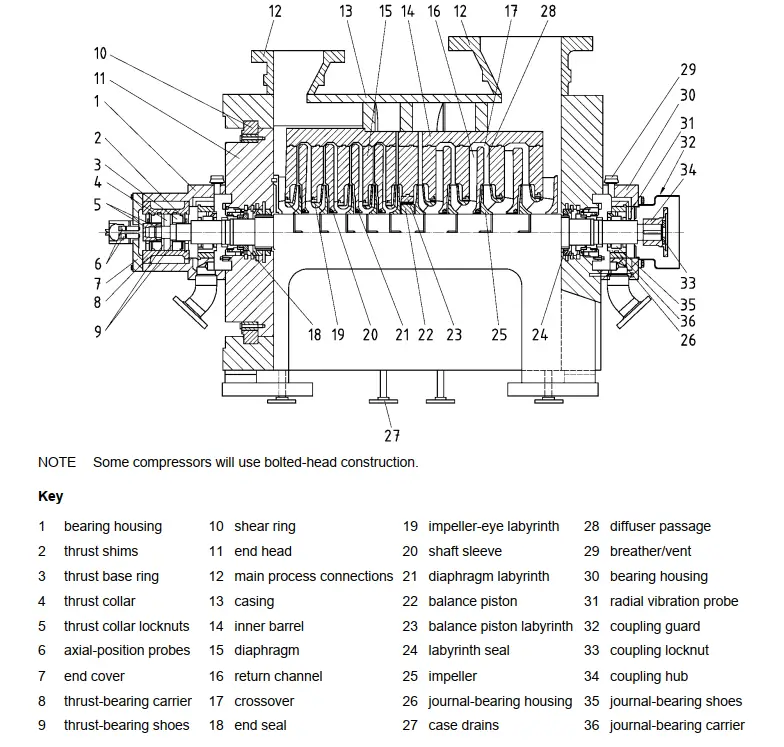

The standard covers aspects like the design of rotating and stationary elements, materials, casings, fabrications, inspection, and more. For pipe stress engineers, API 617 is very important because it provides the allowable nozzle load equations in Annexure E of the standard. At the time of writing this article, the latest edition of API 617 is the Ninth edition, April 2022. Fig. 1 below provides the nomenclature of a typical centrifugal compressor as per API 617.

Note that API standard 617 is not applicable for fans, axial inflow expanders, and integrally geared centrifugal plant and instrument air compressors.

Importance of API 617

It is crucial because it establishes guidelines to ensure the reliability, safety, and performance of centrifugal compressors, which are critical components in various industrial processes. Adhering to API 617 helps manufacturers produce high-quality compressors, while operators can trust that their equipment meets stringent standards for safe and efficient operation.

API 617 outlines several key requirements for centrifugal compressors, including design parameters such as pressure and temperature limits, materials of construction, rotor dynamics, surge control, and vibration analysis. It also specifies testing procedures to validate performance, including mechanical running tests, overspeed tests, and performance testing under various operating conditions. Additionally, API 617 requires compliance with relevant codes and standards such as ASME, ISO, and ANSI to ensure consistency and quality.

API 617 has significant implications for both manufacturers and operators of centrifugal compressors. For manufacturers, compliance with API 617 standards is essential for gaining market acceptance, ensuring product quality, and meeting customer requirements. It requires rigorous design, testing, and documentation processes, which can increase manufacturing costs but also improve product reliability and competitiveness. For operators, API 617 compliance assures equipment reliability, safety, and performance, reducing the risk of unplanned downtime, accidents, and costly repairs.

Applications of API 617

API Standard 617 finds its applications in the following areas:

- Refinery and Petrochemical Industries: These compressors are commonly found in refineries and petrochemical plants. They play a crucial role in processes like gas handling, compression, and transportation.

- Gas Processing Plants: API 617 compressors are essential for handling gases in gas processing facilities. They ensure efficient compression and flow of gases.

- Chemical Industries: In chemical manufacturing, these compressors are used for various purposes, including reactor feed, hydrogen compression, and product separation.

- Gas Transmission Pipelines: For transporting natural gas over long distances, compressors meeting API 617 standards are employed to maintain pressure and flow.

- Power Generation: In power plants, these compressors assist in gas turbine operation, where they compress air for combustion.

- Industrial Processes: From air separation to cryogenic applications, these compressors serve diverse industrial needs.

Note that, continuous monitoring of parameters like radial vibration, axial position, and temperature using machinery management systems is crucial for their reliable operation

API 617 Vibration Limits

API 617 provides guidelines for acceptable vibration levels for centrifugal compressors. The standard specifies vibration limits based on different operating conditions and locations within the compressor. However, it’s important to note that specific vibration limits can vary depending on factors such as compressor type, size, and application. Generally, API 617 recommends the following vibration limits:

Radial Vibration:

For general-purpose compressors, API 617 typically recommends a maximum allowable radial vibration limit of 0.1 mils (0.00254 mm) peak-to-peak at the bearing housing or compressor casing. For critical machinery applications, such as those involving high-speed compressors or machinery operating in sensitive environments, more stringent vibration limits may be specified.

Axial Vibration:

API 617 typically sets a maximum allowable axial vibration limit of 0.2 mils (0.00508 mm) peak-to-peak at the bearing housing or compressor casing.

Torsional Vibration:

Torsional vibration limits are also addressed in API 617, especially for geared compressors where torsional vibrations can affect the integrity of the gearbox and other components. However, specific limits may vary based on the compressor’s design and operating conditions.

API 617 Datasheet

In Annex A, API 617 provides some sample datasheets that outline the requirements, guidelines, and standards for the design, manufacturing, and testing of centrifugal compressors. However, manufacturers often create datasheets based on API 617 requirements to document key specifications and performance characteristics of their centrifugal compressors.

A typical API 617 datasheet usually includes the following information:

General Information:

- Manufacturer name and contact details.

- Model or serial number of the compressor.

- Compressor type (e.g., integrally geared, horizontally split, vertically split).

- Application details (e.g., gas compression, refrigeration, air compression).

Design Parameters:

- Design pressure and temperature limits.

- Material specifications for major components (e.g., impellers, casings, bearings).

- Speed range and operating conditions.

- Design codes and standards followed (e.g., ASME, ISO).

- Inlet and Outlet Conditions.

Performance Data:

- Flow rate (capacity) at various operating conditions (e.g., maximum flow, turndown ratio).

- Pressure ratio (discharge pressure to suction pressure ratio) capabilities.

- Efficiency curves or maps showing performance characteristics at different speeds and operating points.

- Power consumption and motor specifications.

Mechanical Features:

- Rotor dynamics analysis results.

- Bearing types and arrangements.

- Sealing arrangements (e.g., labyrinth seals, mechanical seals).

- Coupling details (for integrally geared compressors).

Instrumentation and Control:

- Instrumentation provided for monitoring and control (e.g., vibration sensors, temperature probes).

- Control system capabilities (e.g., surge control, anti-surge valves).

Testing and Compliance:

- Results of mechanical running tests, overspeed tests, and performance testing conducted per API 617 requirements.

- Compliance statements indicating adherence to API 617 standards and relevant codes and regulations.

Warranty and Service:

- Warranty terms and conditions.

- Service and maintenance requirements.

- Contact information for technical support and service inquiries.

It’s essential for API 617 datasheets to accurately reflect the design, performance, and compliance aspects of centrifugal compressors to assist customers in making informed decisions and ensuring proper integration and operation within their systems. Fig. 2 below shows a typical example of a centrifugal compressor data sheet.